Shell Filling

The shell production page explained how to make the empty shell that is now able to be refilled.

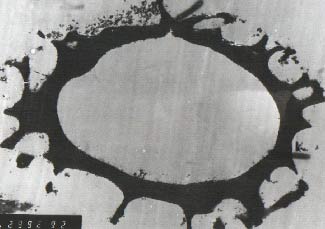

The original genetic material was able to be removed through small pores through the shell. This figure shows a scanning electron micrograph of a section through a Lycopodium clavatum shell.

If the shell is filled and surrounded by acrylic resin, the shell can be microtomed (see below) and viewed under a transmission electron microscope, which makes the pores visible.

These pores are then used to refill the centre with active compounds. The shells are elastic and will naturally absorb fats, so if the empty shells are pressed to 15 tonnes per sq. cm and oil added, the oil will enter the shells and form a dry powder. In order to make this happen quickly a penetrating aiding ingredient may be used. Video 1 shows what happens when sunflower oil and a small amount of ethanol are added to a compressed tablet of Lycopodium clavatum.

Adding an oil or mixture to the uncompressed shells in powder form will also result in the shells being filled with oil. The speed can be increased by applying a vacuum.

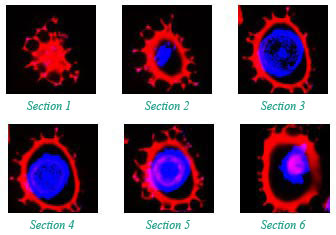

Confocal laser scanning microscopy can be used to show that the material is in fact microencapsulated within the shell. Video 2 shows a scan through a filled Lycopodium clavatum exine as does the series of images shown below.

Stepwise sections of encapsulated Nile red dye.

The exines were washed with ethanol-water and show

no trace of dye on the surface

A very wide variety of substances are able to be encapsulated, some of which are shown in these confocal images.

In order to get controlled release or to provide added protection for the encapsulated material a co-encapsulent is used. This is another material which can block up the spores or coat the shell on the inside or out. Often gums or starches are capable of carrying out this function, but specially developed compounds such as Eudragit ® can also be used. Depending upon the active ingredient and this co-encapsulent, the two may be added together as a mixture. Alternatively the exine shell is partially filled with the active substance and dried where necessary. The powder produced is then added to a solution/dispersion of the protecting ingredient where it too is absorbed into or onto the shell. A further drying stage is then usually required.